INSUBCONTINENT EXCLUSIVE:

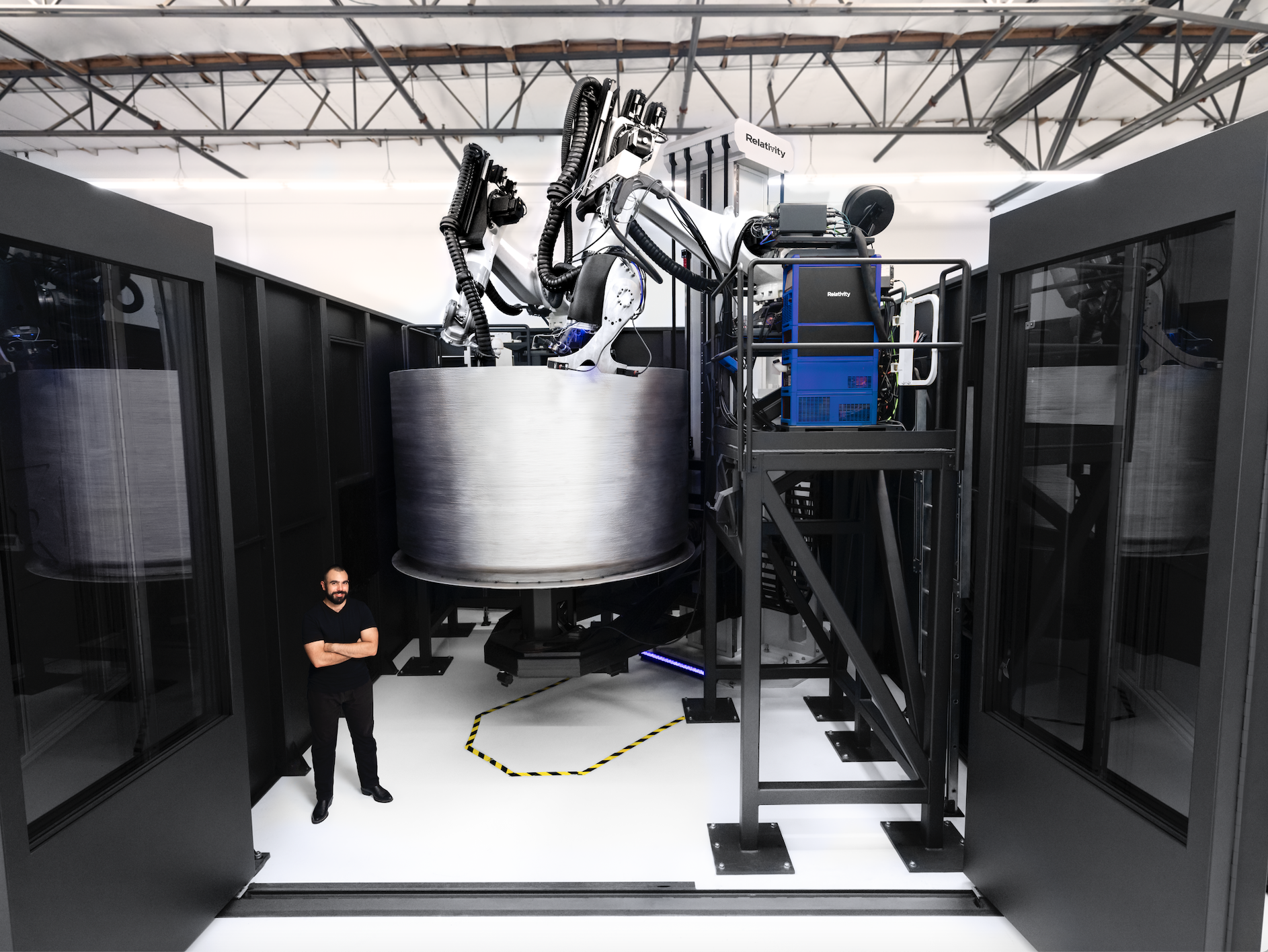

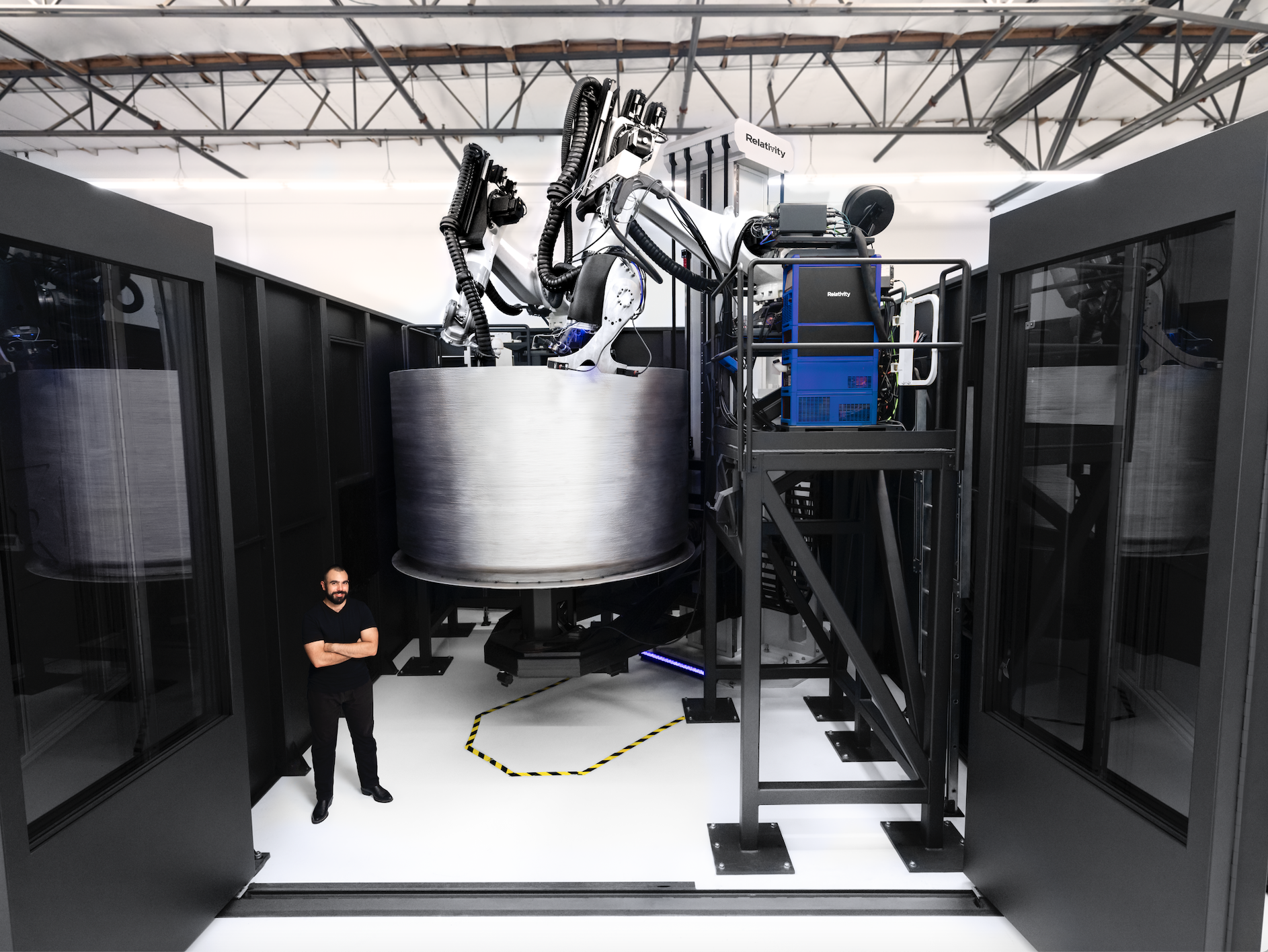

of 3D-printed parts, from the engines to the fuselage and everything in between, the company has been able to continue producing its

prototypes essentially uninterrupted

Relativity has been classified an essential business, as have most companies operating in anything related to aerospace or defense, but

Ellis said that they took steps very early to address the potential threat of COVID-19 and ensure the health and safety of their staff

As early as March 9, when the disease was really first starting to show up in the United States and before any formal restrictions or

partially because with our automated printing technology we were able to have very, very few people in the factory and still keep printers

entire production factory floor with just one person on-site is a tremendous competitive advantage in the current situation, and a way to

Ellis added that the company has already been operating between multiple locations, including teams at Cape Canaveral, Florida, as well as

at Stennis Space Center in Mississippi and at its headquarters in LA

Relativity also had a further distributed workforce with a few employees working remotely from locations across the U.S, and it focused

including hourly workers, their full regular wage

All of this stems from a business model that in retrospect, seems prescient, but that Ellis says actually just has significant advantages in

coronavirus crisis will impact their overall schedule in terms of planned launch activities, which includes flying their first 3D-printed

vehicle in 2021, they anticipate being able to make plenty of progress through remote work and a production line that can easily comply with

social isolation guidelines

could prove a model for manufacturing businesses of all stripes to emulate once this moment has passed.