INSUBCONTINENT EXCLUSIVE:

Getting the hang of through-hole soldering is tricky for those of us tinkering at home with our irons, spools, flux, and, sometimes, braids

It's almost reassuring, then, to learn that through-hole soldering was also a pain for a firm that has made more than 60 million products

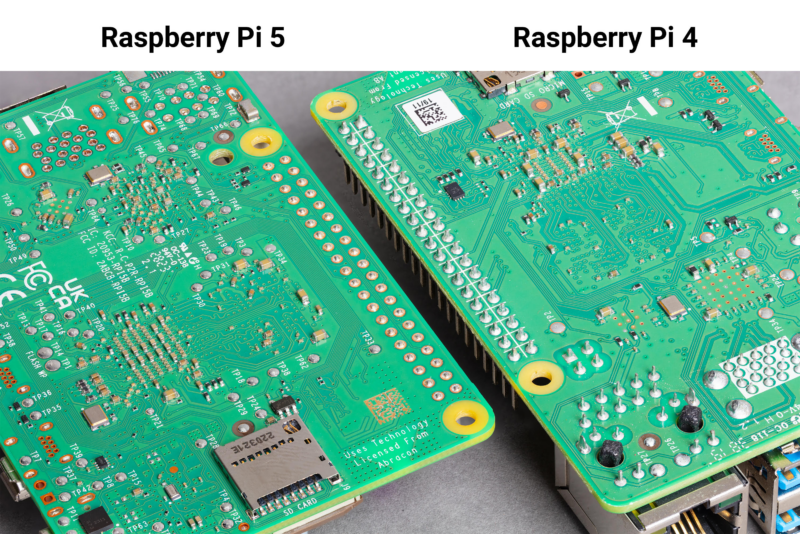

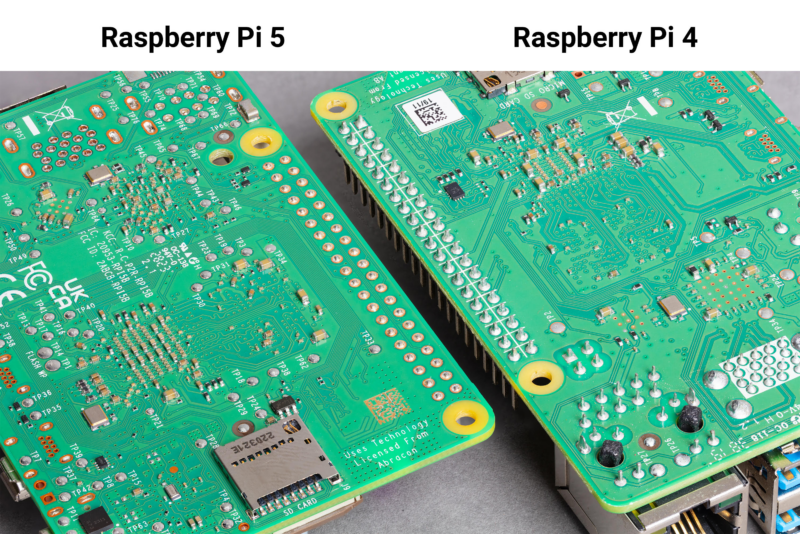

with it.Raspberry Pi boards have a combination of surface-mount devices (SMDs) and through-hole bits

SMDs allow for far more tiny chips, resistors, and other bits to be attached to boards by their tiny pins, flat contacts, solder balls, or

For those things that are bigger, or subject to rough forces like clumsy human hands, through-hole soldering is still required, with leads

poked through a connective hole and solder applied to connect and join them securely.The Raspberry Pi board has a 40-pin GPIO header on it

that needs through-hole soldering, along with bits like the Ethernet and USB ports

These require robust solder joints, which can't be done the same way as with SMT (surface-mount technology) tools

"In the early days of Raspberry Pi, these parts were inserted by hand, and later by robotic placement," writes Roger Thornton, director of

applications for Raspberry Pi, in a blog post

The boards then had to go through a follow-up wave soldering step.Now Pi boards have their tiny bits and bigger pieces soldered at the same

time through an intrusive reflow soldering process undertaken with Raspberry Pi's UK manufacturing partner, Sony

After adjusting component placement, the solder stencil, and the connectors, the board makers could then place and secure all their

components in the same stage.