INSUBCONTINENT EXCLUSIVE:

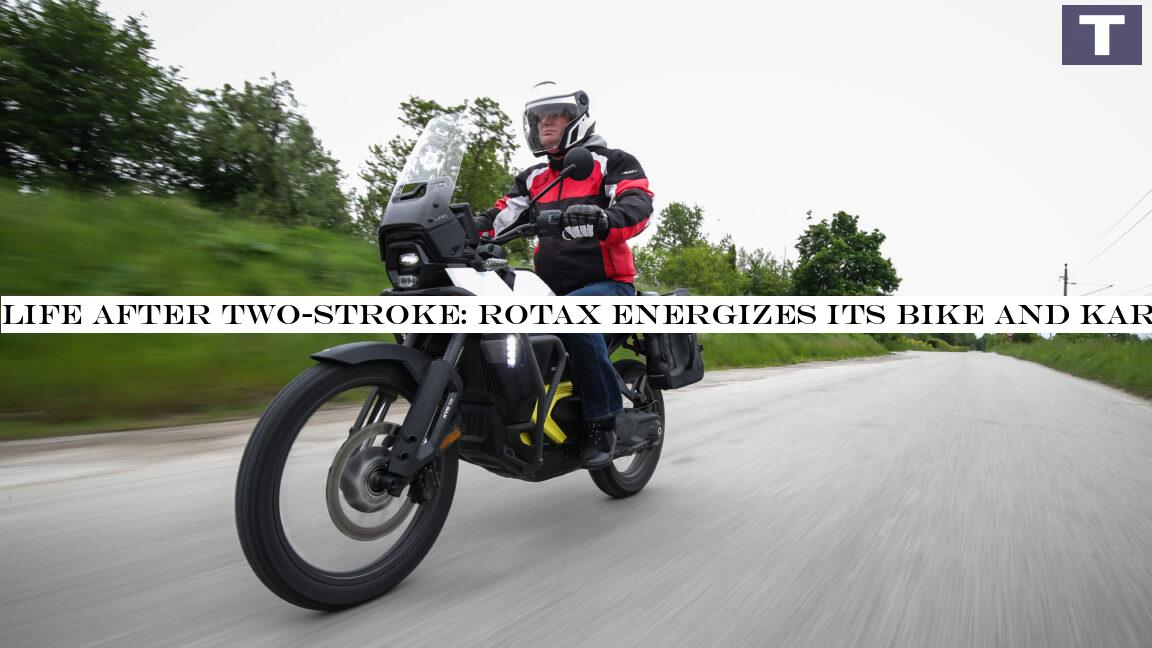

the two Can-Am bikes ready to deliver the expected power at any speed

It's not only a tremendous feat of engineering, but on the road, it can mean the difference between life and death.

The Can-Am Pulse

We straddle a motor connected to two wheels with a metal frame holding it all together

While astride these machines, it's important that everything works as expected

More so than inside a car, counting on the brakes and powertrain to perform as anticipated is extremely important

Thermal fade in a car isn't great

Thermal fade in a motorcycle could lead to a life-threatening situation.For a company that has been building motors for itself and other

bike makers, the importance of creating a vehicle that performs as expected is likely not lost on Rotax.The company is also aware that the

rest of the motorcycle industry is likely keeping an eye of the Can-Am bike sales

"They know what we did in the power sports industry, that we are a serious company with design, development, manufacturing capabilities, an

international footprint, an international global supply base, and we have the knowledge to do great products

If I [were] them, I would be watching us," Gebetshuber said.Like other businesses, Rotax is trying to deal with the fallout of the United

States' chaotic tariff situation

Gebetshuber notes that the company doesn't want to comment on politics but, "what we can say is the environment is currently very difficult,

because changes are happening faster than we're able to react."

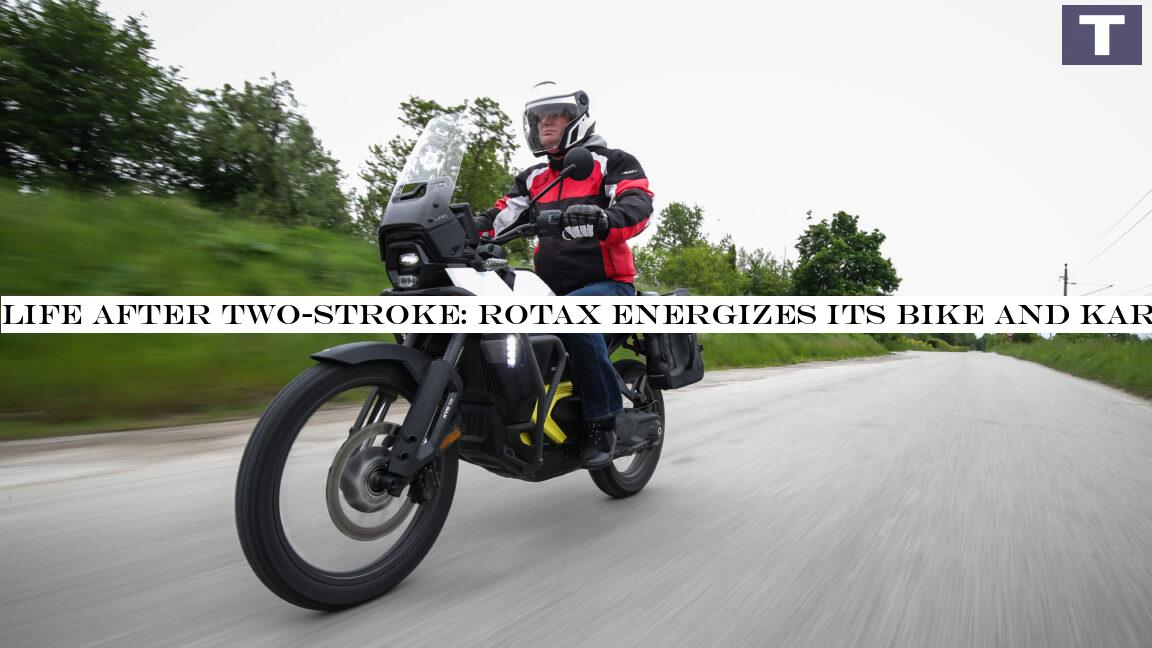

You'll find Rotax's motors in a number of other OEMs' bikes.

Credit:

Rotax

It does help with development that nearly everything is done in-house

The motors are built at a Rotax facility

The bikes are put together at another

Development is done in Austria

Nearly everything on the Can-Am bikes is either built by Rotax or, in the case of the inverter on the electric platform, built to Rotax