Music

Trailers

DailyVideos

India

Pakistan

Afghanistan

Bangladesh

Srilanka

Nepal

Thailand

StockMarket

Business

Technology

Startup

Trending Videos

Coupons

Football

Search

Download App in Playstore

Download App

Best Collections

Technology

As remote working booms around the world in response to the coronavirus crisis, demand for video calls has surged dramatically. But despite the fact that video meeting software is now more reliable and user-friendly than ever, setting up and joining a video call can still feel intrusive and somewhat of a chore.

Typically it requires workers to divert their full attention to a discussion with one or more colleagues, with the video chat client taking over their entire computer screen. While this makes sense for important meetings, it also sets a higher bar for more casual interactions and makes it more difficult to take notes or otherwise share focus between the video chat and other apps.

To read this article in full, please click here

- Details

- Category: Technology Today

Read more: Video chat app Around could be a harbinger of ‘always-on’ video

Write comment (94 Comments)To conserve the economy we need to decrease video transmission capacity usage-- currently (upgraded)

Internet capacity is robust, but the massive increase in global consumption is pushing usage beyond its usual spike, EU regulators have warned.

It is probable that streaming media consumption, gaming and video collaboration are responsible for most of this additional demand. To maintain our connected culture during the current crisis, individuals, enterprises and big tech firms must cut down on their bandwidth usage — and the best way to do so is to reduce the use of video.

To read this article in full, please click here

- Details

- Category: Technology Today

Apple has shared many more details to explain how pointer and trackpad supportwill work with iPads, providing video, guidance notes and a senior level company presentation.

What is pointer and trackpad support on iPad?

Apple now supports trackpads in iPad OS 13.4.

That doesn&t mean you use the trackpad on an iPad in the same way you use a pointing device on a Mac or other system. Instead, the company has developed a refined experience thatunique to the tablet itself.

In other words, rather than deliver a ‘me-too& experience, the company has thought deeply about how these things work in order to develop a control system that feels natural, intuitive and unique.

To read this article in full, please click here

- Details

- Category: Technology Today

Read more: Everything you need to know about Apple's pointer support for iPad

Write comment (94 Comments)

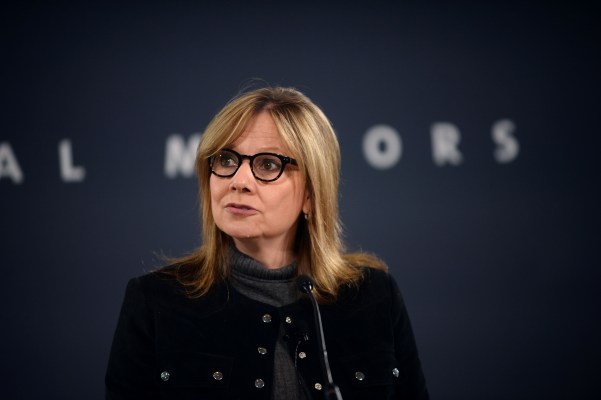

GM said Friday that it is working with Ventec Life Systems to help increase production of respiratory care products such as ventilators that are needed by a growing number of hospitals as the COVID-19 pandemics spreads throughout the U.S.

The partnership is part of StopTheSpread.org, a coordinated effort of private companies to respond to COVId-19, a disease caused by coronavirus.

Ventec will use GMlogistics, purchasing and manufacturing expertise to build more ventilators. The companies did not provide further details such as when production might be able to ramp up or how many ventilators would be produced.

GM Chairman and CEO Mary Barra said in a statement that GM is working closely with Ventec to rapidly scale up production.

&We will continue to explore ways to help in this time of crisis,& Barra added.

The need for ventilators is urgent as cases of COVID-19 pop up with increasing frequency as widespread testing begins. While some people with COVID-19 reported more mild symptoms, others have experienced severe respiratory problems and need to be hospitalized.

The shortage has prompted automakers to investigate ways of ramping up ventilator production. Volkswagen and Ford have reportedly either talked to the White House or committed to looking at the problem. Volkswagen said Friday it has created a task force to look into using 3D printing to make hospital ventilators.

Elon Musk tweeted Friday that Tesla and SpaceX employees are &working on ventilators& even though he doesn&t believe they will be needed.His confirmation on Twitter that both of the companies he leads are working on ventilators comes a day after New York City MayorBill de Blasiomade a direct plea to Musk to help alleviate a shortage at hospitals gearing up to combat COVID-19.

Musk didn&t provide specifics what &working on ventilators& means, what Tesla factory might be used, the possible capacity or when he planned to begin production.

- Details

- Category: Technology Today

Read more: GM and Ventec Life Systems partner to ramp up production of ventilators

Write comment (97 Comments)

Itmany moons ago, and this help desk pilot fish gets a call from a senior vice president complaining that his floppy disk drive is broken.

&I went to take a look at the problem,& says fish, &and was met with ‘Why don&t we buy some decent computers for a change instead of this cheap junk?&

&I shrugged and told him that I thought his problem was out of the ordinary.

&I then removed the floppy disk from his Zip drive, inserted it into the floppy drive and said, ‘I think it's OK now.&&

One of Sharkybetter qualitiesis his care in filing off the identifying marks from each true tale of IT life. So send me yours at This email address is being protected from spambots. You need JavaScript enabled to view it.. You can also subscribe to the Daily Shark Newsletter.

To read this article in full, please click here

- Details

- Category: Technology Today

Read more: Flashback Friday: Oh yes, definitely a quality problem!

Write comment (99 Comments)

Panasonic is pulling its 3,500 employees from the massive Nevada factory it operates with partner Tesla over concerns about the spread of COVID-19.

The company said Friday it will ramp down operations early next week and then close for 14 days. The move only affects Panasonic employees. Tesla also employs thousands of workers at the so-called Gigafactory 1 in Sparks, Nevada.

Tesla could not be reached for comment.

Gigafactory 1, which broke ground in June 2014, is a critical ingredient in Teslagoal to accelerate the worldtransition to sustainable energy by expanding global battery capacity and reducing the cost of electric vehicles. And Panasonic has been its most important partner as a supplier and partner in that project.

The factory produces Model 3 electric motors and battery packs, in addition to Teslaenergy storage products, Powerwall and Powerpack. Panasonic makes the cells, which Tesla then uses to make battery packs for its electric vehicles.

Here is the statement from Panasonic spokesperson AlbertoCanal

Panasonic is committed to safeguarding the health and well-being of every employee. The Panasonic factory in Sparks, Nevada will begin ramping down operations early next week and will then close for 14 days. Employees impacted by the closure will receive full pay and benefits for the 14-day period. In the meantime, Panasonic has enacted several measures to enhance the cleanliness of the facility, encourage social distancing, and enable simple, safe and effective behaviors. During the 14-day period, the facility will undergo intensive cleaning.

Without Panasonic, Tesla could face a bottleneck in the supply chain. Tesla has agreed to suspend production beginning March 23 at its Fremont, Calif., factory, where it assembles the Model X, Model S, Model 3 and now the Model Y.

- Details

- Category: Technology Today

Read more: Tesla partner Panasonic is shutting down its operations at Nevada gigafactory

Write comment (95 Comments)Page 1150 of 1418

9

9